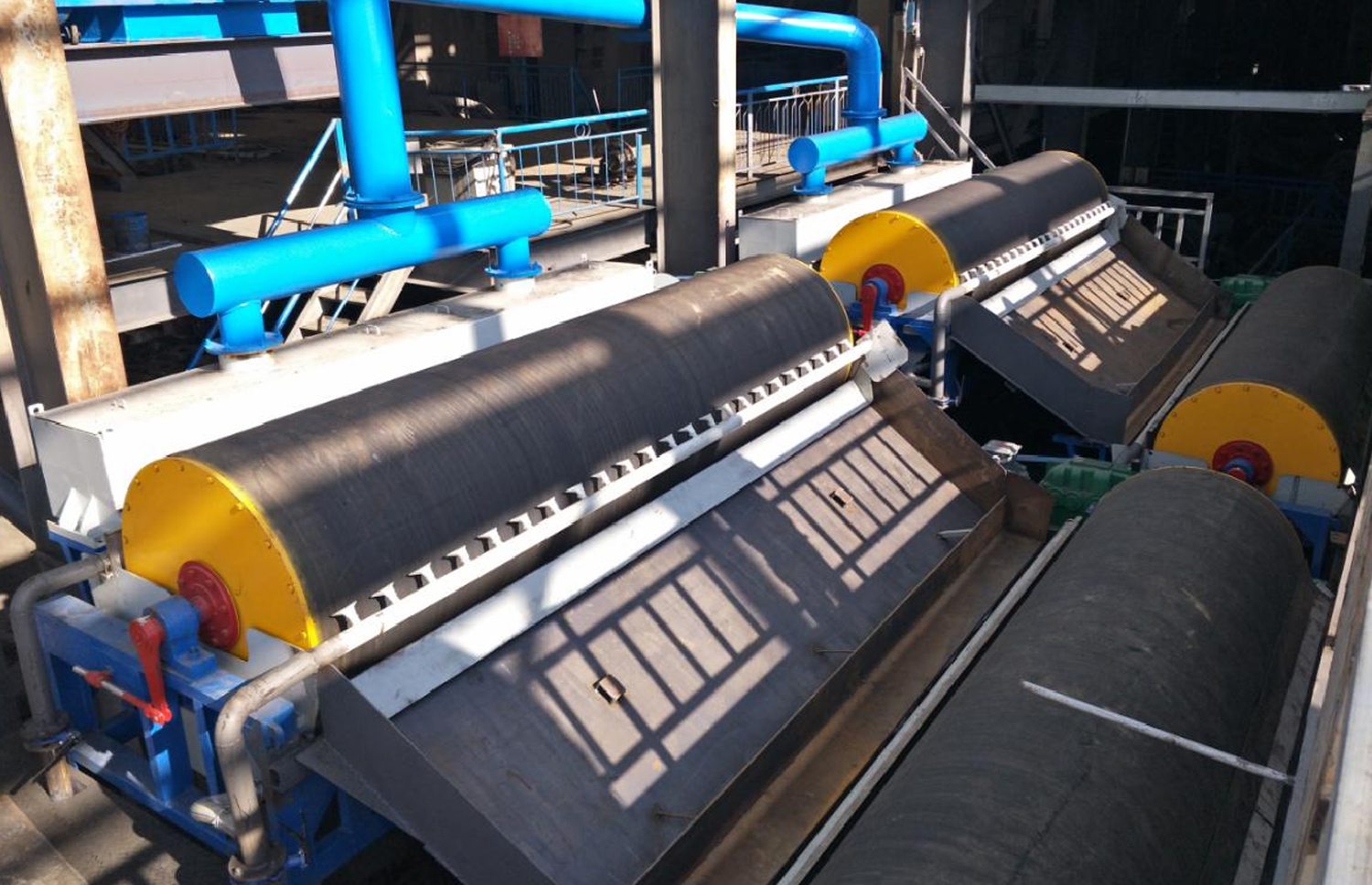

TGTM tower mill

TGTM tower mill

Features and benefits

○ Energy Savings: Compared to traditional ball mill, typically reduction 30-35% and 35-50% in 2nd and 3rd grinding stage respectively.

○ Lower grinding media consumption: typically 60-70% of traditional ball mill.

○ Final grinding particle size: up to 20 microns.

○ The overgrinding decrease of valued minerals: processing and dewatering easily and efficiently.

○ Higher operating rate and lower maintenance cost.

○ Lower floor space and quicker installation.

○ Lower noise: Typically below 90 dB(A).

CASE

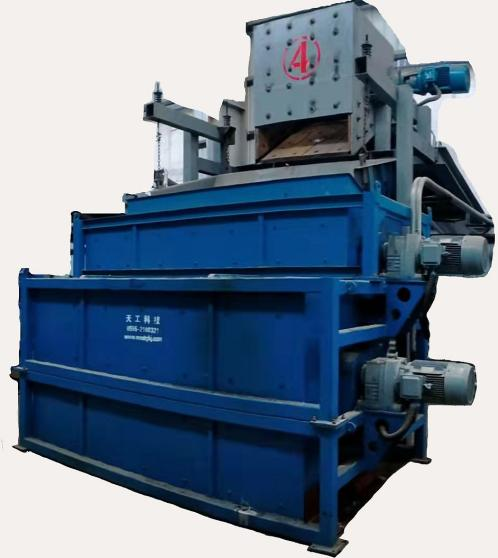

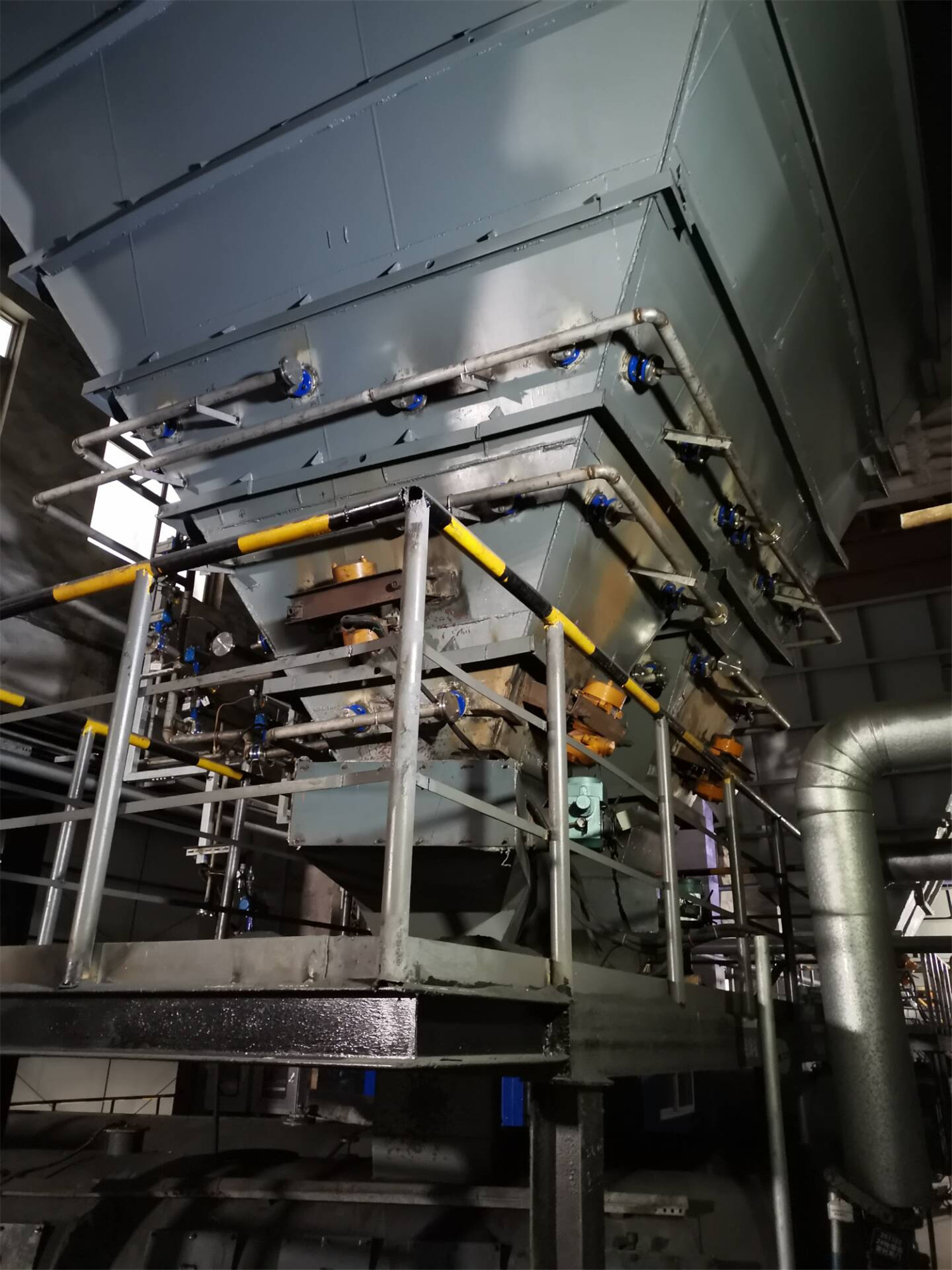

TGTM-630 tower mill in ShangQing Mining | TGTM-250 tower mill in ShanDong Gold Group | TGTM tower mills in fluorite beneficiation plant of BaoSteel Kings mineral processing Co. Ltd. | TGTM1000 tower mill & T-GCT magnetic separators (fine) in NanShan mining |